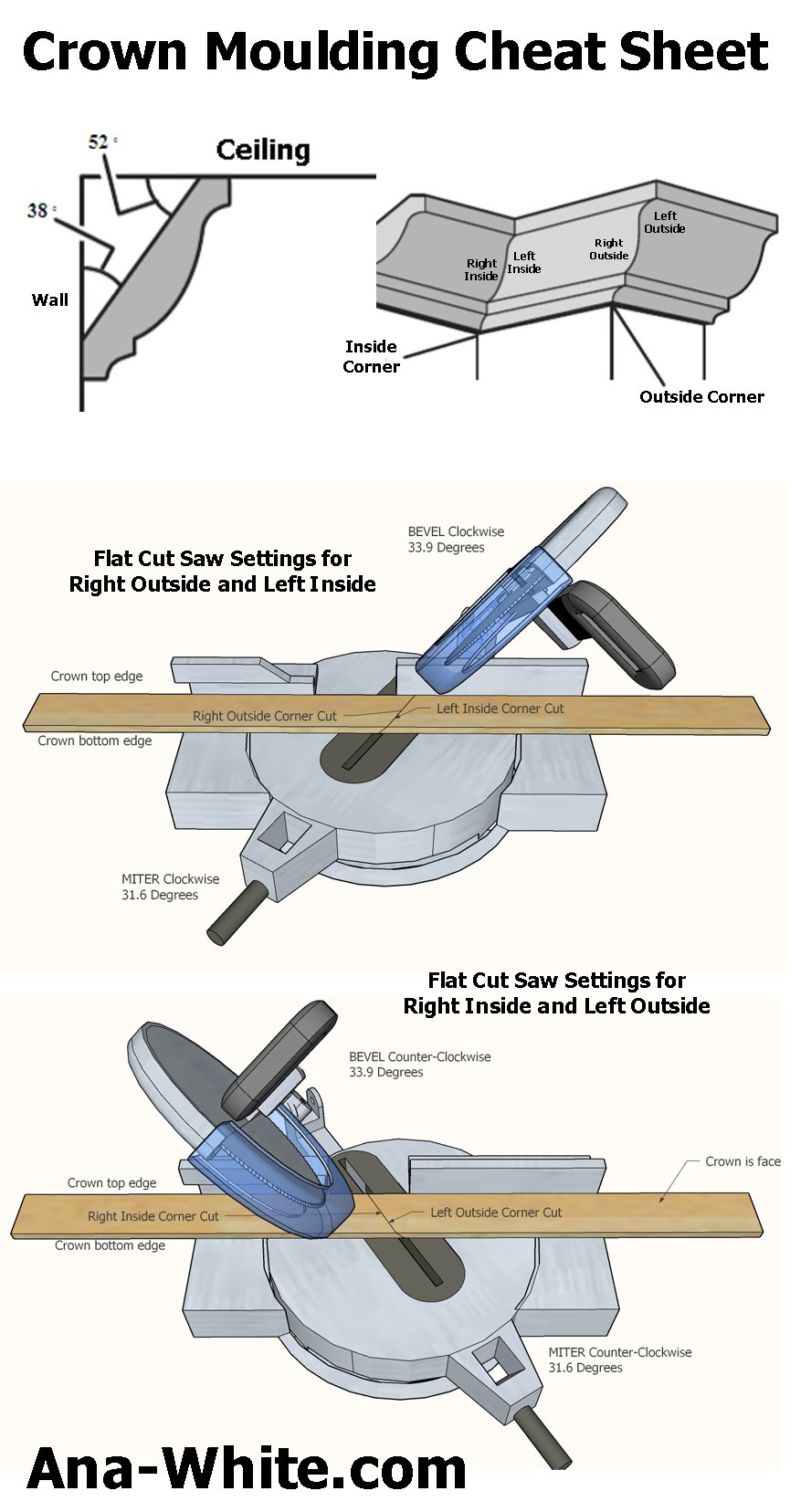

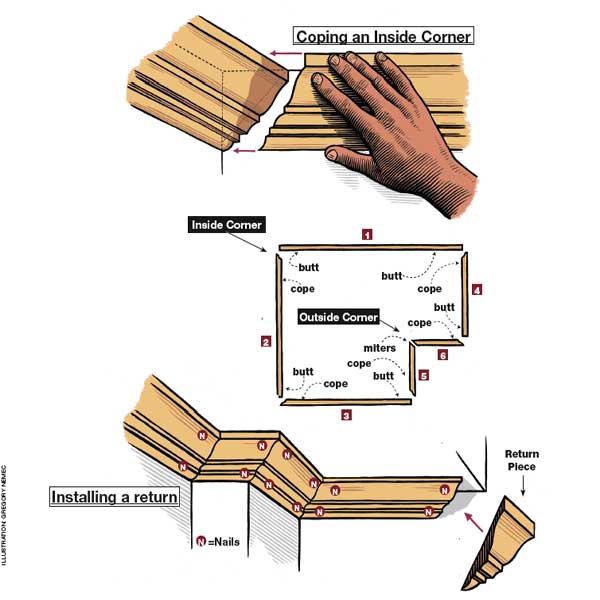

Crown Moulding Cheat Sheet - Place molding in compound miter saw with broad back surface down flat on saw table (visible decorative surface up). On one side, the molding is cut square and butts tight to the wall. On the other side, the molding is “coped” to match the profile of its neighbor. Set saw miter and bevel. We did a lot of searching and found a lot of information about crown molding but there was always something missing. All measures are given in degrees. Just as with standard crown, backing and blocking are important elements for a solid installation. If you’re able to open up the ceiling, install. So print this chart and carry it in your truck.

On the other side, the molding is “coped” to match the profile of its neighbor. On one side, the molding is cut square and butts tight to the wall. Set saw miter and bevel. Just as with standard crown, backing and blocking are important elements for a solid installation. We did a lot of searching and found a lot of information about crown molding but there was always something missing. So print this chart and carry it in your truck. All measures are given in degrees. Place molding in compound miter saw with broad back surface down flat on saw table (visible decorative surface up). If you’re able to open up the ceiling, install.

So print this chart and carry it in your truck. Just as with standard crown, backing and blocking are important elements for a solid installation. We did a lot of searching and found a lot of information about crown molding but there was always something missing. If you’re able to open up the ceiling, install. All measures are given in degrees. Set saw miter and bevel. On one side, the molding is cut square and butts tight to the wall. Place molding in compound miter saw with broad back surface down flat on saw table (visible decorative surface up). On the other side, the molding is “coped” to match the profile of its neighbor.

Installing Crown Moulding the Easy Way Ana White

Just as with standard crown, backing and blocking are important elements for a solid installation. So print this chart and carry it in your truck. If you’re able to open up the ceiling, install. We did a lot of searching and found a lot of information about crown molding but there was always something missing. On one side, the molding.

How To Install Crown Molding To Kitchen

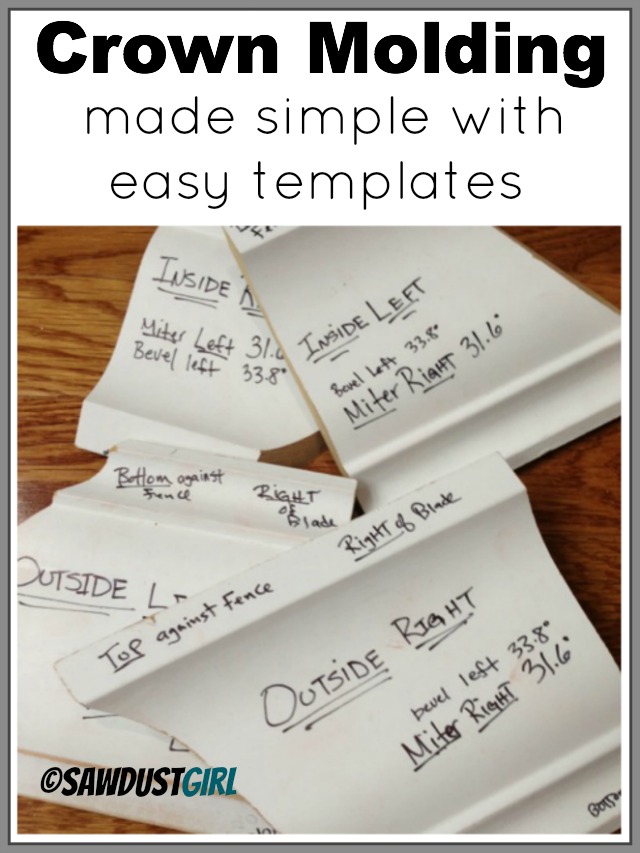

Place molding in compound miter saw with broad back surface down flat on saw table (visible decorative surface up). All measures are given in degrees. On one side, the molding is cut square and butts tight to the wall. Set saw miter and bevel. If you’re able to open up the ceiling, install.

Crown Molding Cut Cheat Sheet at Ronald Alvarez blog

We did a lot of searching and found a lot of information about crown molding but there was always something missing. Place molding in compound miter saw with broad back surface down flat on saw table (visible decorative surface up). So print this chart and carry it in your truck. Just as with standard crown, backing and blocking are important.

Crown Molding Cheat Sheet

So print this chart and carry it in your truck. On one side, the molding is cut square and butts tight to the wall. All measures are given in degrees. We did a lot of searching and found a lot of information about crown molding but there was always something missing. If you’re able to open up the ceiling, install.

Crown Molding Cut Cheat Sheet at Ronald Alvarez blog

On one side, the molding is cut square and butts tight to the wall. Set saw miter and bevel. All measures are given in degrees. Place molding in compound miter saw with broad back surface down flat on saw table (visible decorative surface up). We did a lot of searching and found a lot of information about crown molding but.

Crown Molding Cheat Sheet

Set saw miter and bevel. Just as with standard crown, backing and blocking are important elements for a solid installation. We did a lot of searching and found a lot of information about crown molding but there was always something missing. On one side, the molding is cut square and butts tight to the wall. On the other side, the.

Tips and Tricks for Installing Crown Molding.

We did a lot of searching and found a lot of information about crown molding but there was always something missing. Just as with standard crown, backing and blocking are important elements for a solid installation. So print this chart and carry it in your truck. Place molding in compound miter saw with broad back surface down flat on saw.

Crown Molding Cheat Sheet

We did a lot of searching and found a lot of information about crown molding but there was always something missing. Place molding in compound miter saw with broad back surface down flat on saw table (visible decorative surface up). All measures are given in degrees. Just as with standard crown, backing and blocking are important elements for a solid.

Crown Molding Cut Cheat Sheet at Ronald Alvarez blog

On the other side, the molding is “coped” to match the profile of its neighbor. On one side, the molding is cut square and butts tight to the wall. If you’re able to open up the ceiling, install. All measures are given in degrees. Set saw miter and bevel.

Crown Molding Cheat Sheet

All measures are given in degrees. We did a lot of searching and found a lot of information about crown molding but there was always something missing. Place molding in compound miter saw with broad back surface down flat on saw table (visible decorative surface up). If you’re able to open up the ceiling, install. On the other side, the.

All Measures Are Given In Degrees.

On the other side, the molding is “coped” to match the profile of its neighbor. We did a lot of searching and found a lot of information about crown molding but there was always something missing. If you’re able to open up the ceiling, install. Just as with standard crown, backing and blocking are important elements for a solid installation.

Set Saw Miter And Bevel.

So print this chart and carry it in your truck. On one side, the molding is cut square and butts tight to the wall. Place molding in compound miter saw with broad back surface down flat on saw table (visible decorative surface up).