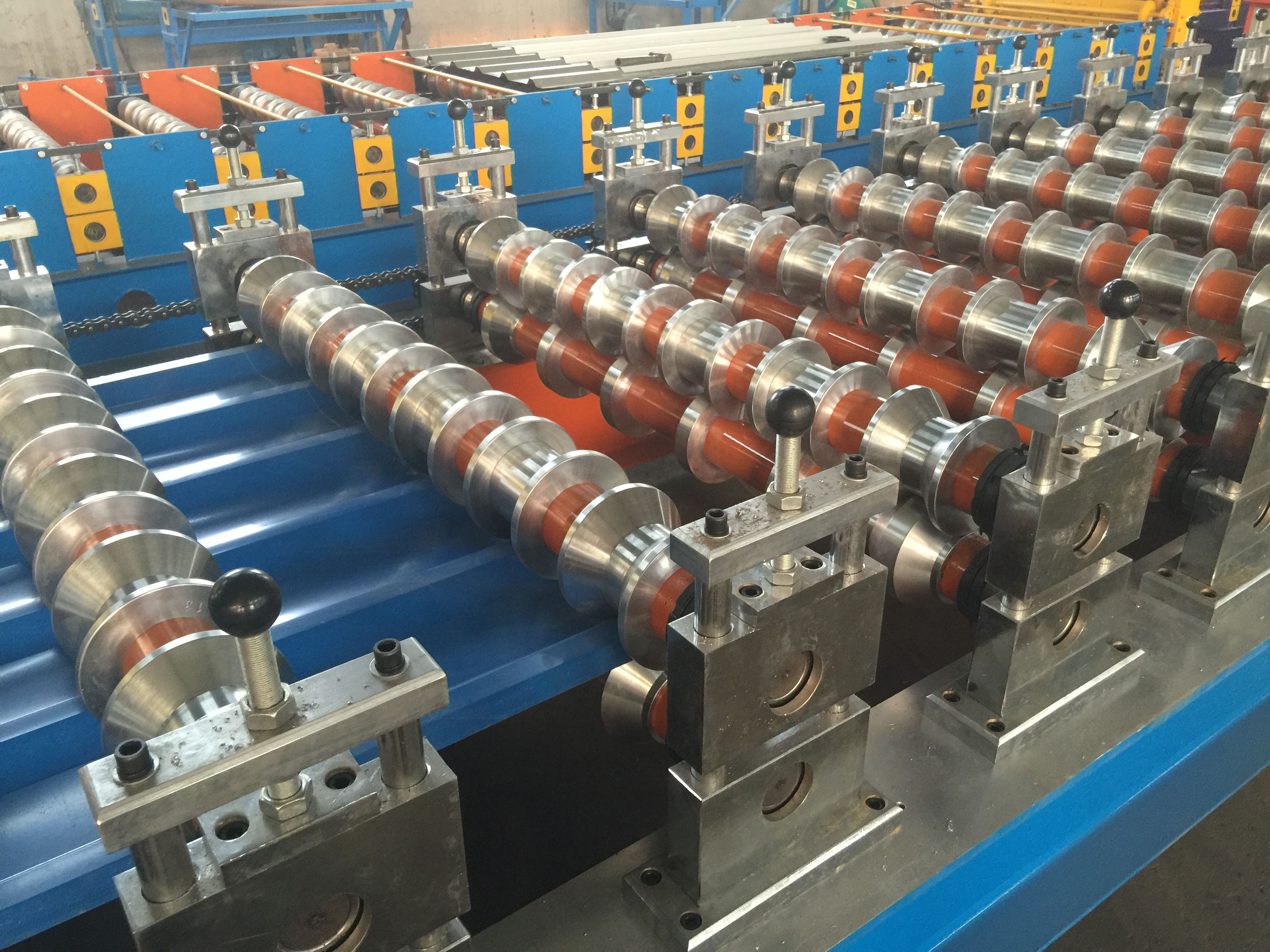

Roll Forming Sheet Metal - Roll forming process involves continuous bending operation of a long strip of sheet metal which is passed through. Determining the best spot to make a cut is important. The sheet metal can be cut at a specific point on a roll forming line. Explore metalforming, llc's advanced metal rollforming systems and rollformers, designed for efficiency and precision in sheet metalworking. Consider this a roll forming design guide. What can a roll forming machine handle in terms of material thickness, size, & bends?

Consider this a roll forming design guide. Explore metalforming, llc's advanced metal rollforming systems and rollformers, designed for efficiency and precision in sheet metalworking. What can a roll forming machine handle in terms of material thickness, size, & bends? Determining the best spot to make a cut is important. Roll forming process involves continuous bending operation of a long strip of sheet metal which is passed through. The sheet metal can be cut at a specific point on a roll forming line.

Consider this a roll forming design guide. Explore metalforming, llc's advanced metal rollforming systems and rollformers, designed for efficiency and precision in sheet metalworking. Determining the best spot to make a cut is important. What can a roll forming machine handle in terms of material thickness, size, & bends? The sheet metal can be cut at a specific point on a roll forming line. Roll forming process involves continuous bending operation of a long strip of sheet metal which is passed through.

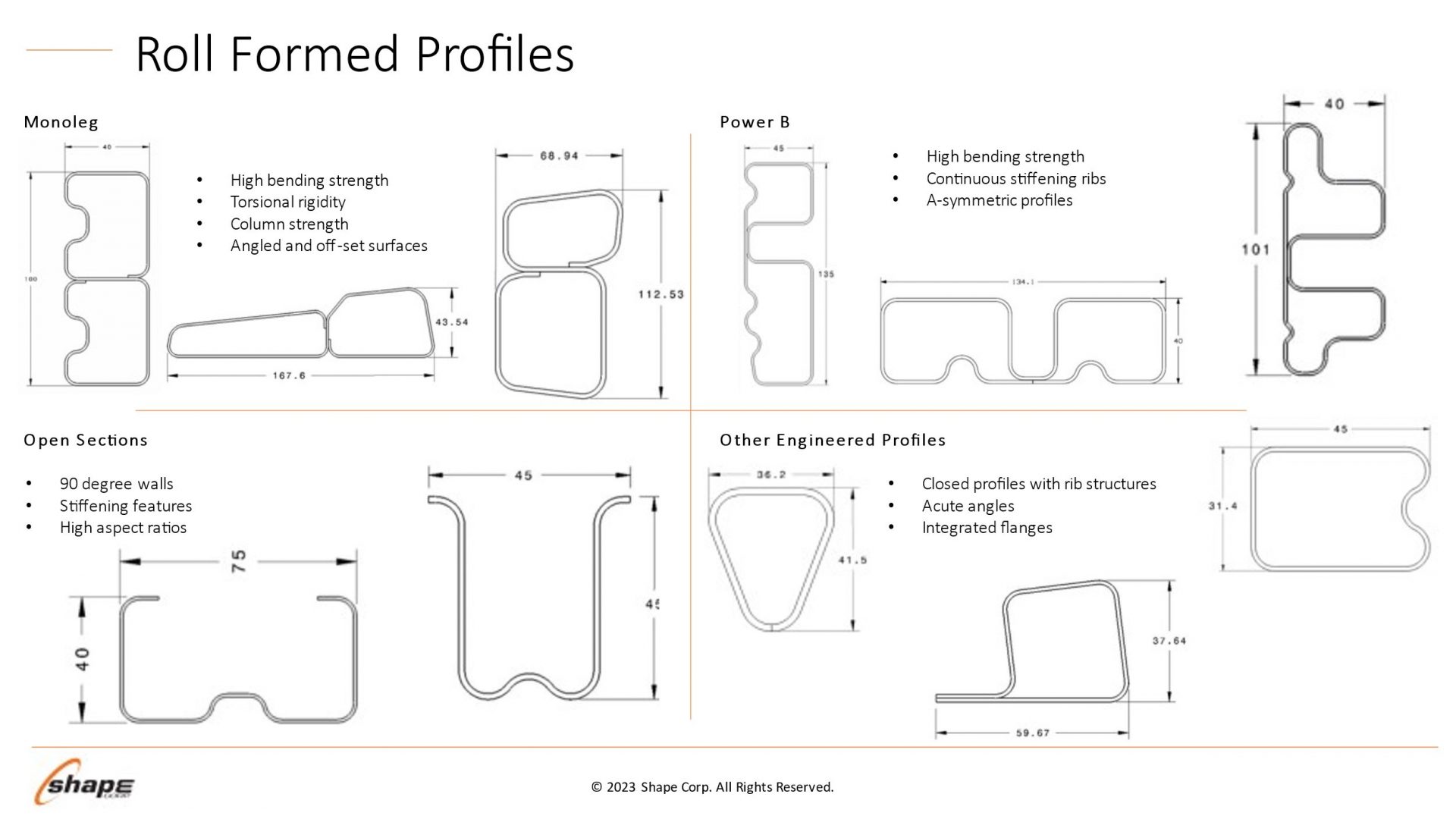

Roll Forming as a Bending Process in Metal Fabrication

Roll forming process involves continuous bending operation of a long strip of sheet metal which is passed through. Consider this a roll forming design guide. What can a roll forming machine handle in terms of material thickness, size, & bends? Determining the best spot to make a cut is important. Explore metalforming, llc's advanced metal rollforming systems and rollformers, designed.

Roll Forming Sheet Metal Fabrication Yarder Manufacturing

What can a roll forming machine handle in terms of material thickness, size, & bends? The sheet metal can be cut at a specific point on a roll forming line. Explore metalforming, llc's advanced metal rollforming systems and rollformers, designed for efficiency and precision in sheet metalworking. Determining the best spot to make a cut is important. Roll forming process.

Roll Forming Metal Components Standard & Custom Roll Forming

Roll forming process involves continuous bending operation of a long strip of sheet metal which is passed through. Explore metalforming, llc's advanced metal rollforming systems and rollformers, designed for efficiency and precision in sheet metalworking. The sheet metal can be cut at a specific point on a roll forming line. What can a roll forming machine handle in terms of.

Roll Forming Design Considerations Part 2 of 2 Formtek Metal

Determining the best spot to make a cut is important. The sheet metal can be cut at a specific point on a roll forming line. Consider this a roll forming design guide. Explore metalforming, llc's advanced metal rollforming systems and rollformers, designed for efficiency and precision in sheet metalworking. Roll forming process involves continuous bending operation of a long strip.

How Steel Properties Influence the Roll Forming Process AHSS Guidelines

Explore metalforming, llc's advanced metal rollforming systems and rollformers, designed for efficiency and precision in sheet metalworking. Consider this a roll forming design guide. Determining the best spot to make a cut is important. What can a roll forming machine handle in terms of material thickness, size, & bends? Roll forming process involves continuous bending operation of a long strip.

Sheet Metal Roll Forming Roll Forming The Ultimate Guide 2021

What can a roll forming machine handle in terms of material thickness, size, & bends? The sheet metal can be cut at a specific point on a roll forming line. Determining the best spot to make a cut is important. Consider this a roll forming design guide. Explore metalforming, llc's advanced metal rollforming systems and rollformers, designed for efficiency and.

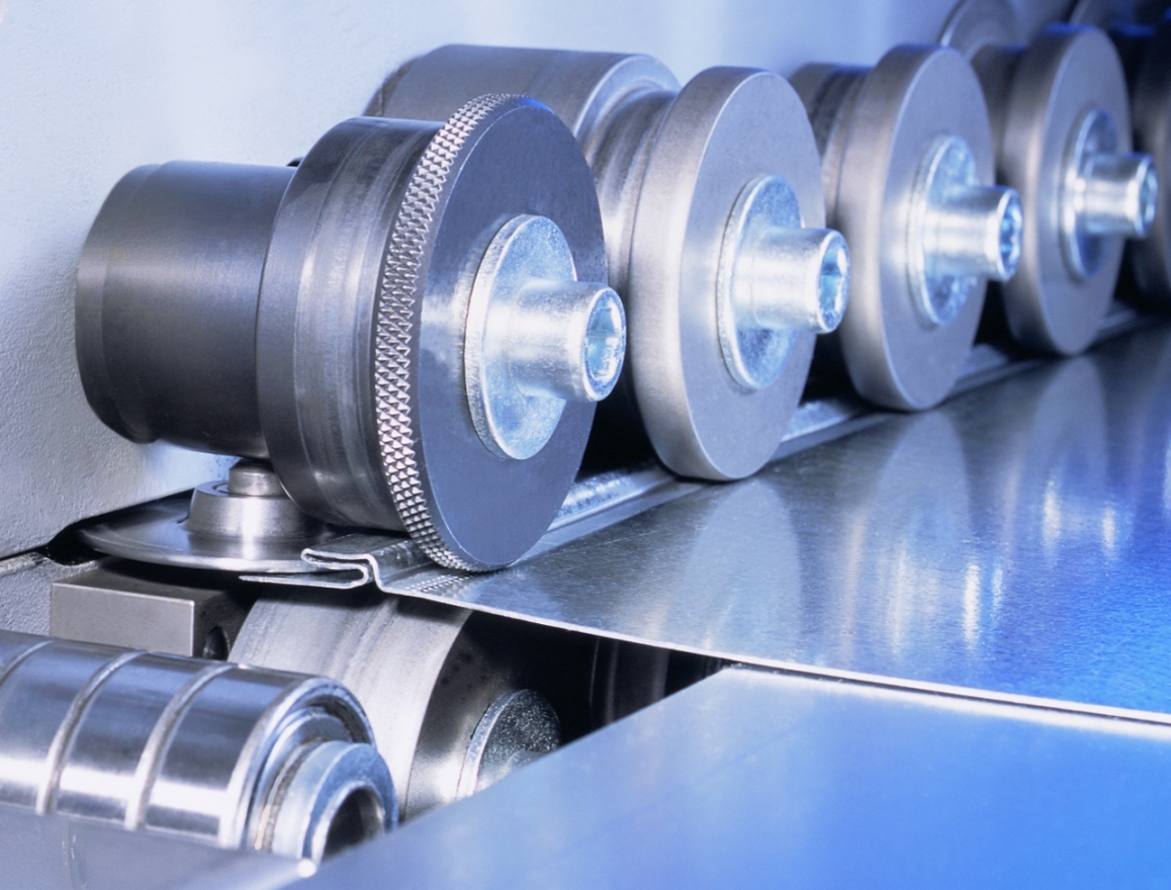

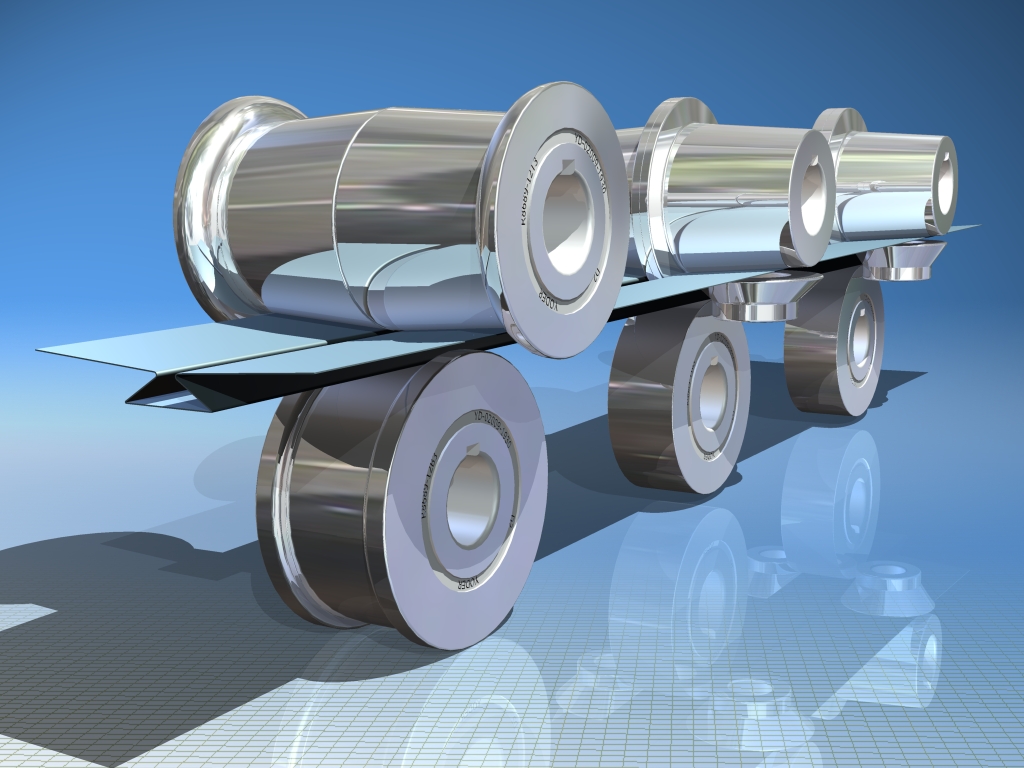

Sheet metal roll forming machines

Roll forming process involves continuous bending operation of a long strip of sheet metal which is passed through. Explore metalforming, llc's advanced metal rollforming systems and rollformers, designed for efficiency and precision in sheet metalworking. The sheet metal can be cut at a specific point on a roll forming line. Consider this a roll forming design guide. Determining the best.

Crafting Metal Brilliance The Power of Roll Forming Machines SHJFV

The sheet metal can be cut at a specific point on a roll forming line. What can a roll forming machine handle in terms of material thickness, size, & bends? Roll forming process involves continuous bending operation of a long strip of sheet metal which is passed through. Determining the best spot to make a cut is important. Explore metalforming,.

What is Roll Forming? National Material Company Steel Processing

What can a roll forming machine handle in terms of material thickness, size, & bends? Consider this a roll forming design guide. The sheet metal can be cut at a specific point on a roll forming line. Roll forming process involves continuous bending operation of a long strip of sheet metal which is passed through. Determining the best spot to.

Roll forming YouTube

Determining the best spot to make a cut is important. The sheet metal can be cut at a specific point on a roll forming line. Consider this a roll forming design guide. Explore metalforming, llc's advanced metal rollforming systems and rollformers, designed for efficiency and precision in sheet metalworking. Roll forming process involves continuous bending operation of a long strip.

Roll Forming Process Involves Continuous Bending Operation Of A Long Strip Of Sheet Metal Which Is Passed Through.

Determining the best spot to make a cut is important. Explore metalforming, llc's advanced metal rollforming systems and rollformers, designed for efficiency and precision in sheet metalworking. Consider this a roll forming design guide. What can a roll forming machine handle in terms of material thickness, size, & bends?