Sheet Roller - Our metal slip rollers are designed to form sheet metal into cylindrical. Tell us what size and type of metal you need to form. Make different edge styles on your sheet metal. Slip and plate rolling machines feed sheet metal or metal plates between their long, cylindrical rollers to form flat workpieces into rolls. One of the most popular and widely used methods is sheet metal rolling of flat sheet metal pieces or coiled strips that are processed. We offer three types of metal slip rollers for the fabrication industry. It comes with rollers for turning, wiring, burring, beading, and crimping.

Slip and plate rolling machines feed sheet metal or metal plates between their long, cylindrical rollers to form flat workpieces into rolls. Tell us what size and type of metal you need to form. It comes with rollers for turning, wiring, burring, beading, and crimping. One of the most popular and widely used methods is sheet metal rolling of flat sheet metal pieces or coiled strips that are processed. We offer three types of metal slip rollers for the fabrication industry. Our metal slip rollers are designed to form sheet metal into cylindrical. Make different edge styles on your sheet metal.

It comes with rollers for turning, wiring, burring, beading, and crimping. We offer three types of metal slip rollers for the fabrication industry. Tell us what size and type of metal you need to form. One of the most popular and widely used methods is sheet metal rolling of flat sheet metal pieces or coiled strips that are processed. Our metal slip rollers are designed to form sheet metal into cylindrical. Slip and plate rolling machines feed sheet metal or metal plates between their long, cylindrical rollers to form flat workpieces into rolls. Make different edge styles on your sheet metal.

Manual Sheet Rollers Metal Fabrication Pennine Fabrication

Tell us what size and type of metal you need to form. Our metal slip rollers are designed to form sheet metal into cylindrical. We offer three types of metal slip rollers for the fabrication industry. Make different edge styles on your sheet metal. One of the most popular and widely used methods is sheet metal rolling of flat sheet.

Metal Sheet Roller

Slip and plate rolling machines feed sheet metal or metal plates between their long, cylindrical rollers to form flat workpieces into rolls. We offer three types of metal slip rollers for the fabrication industry. Make different edge styles on your sheet metal. It comes with rollers for turning, wiring, burring, beading, and crimping. Tell us what size and type of.

Heavy Duty Metal Sheet Rolling Machine Stock Image Image of

Make different edge styles on your sheet metal. We offer three types of metal slip rollers for the fabrication industry. Tell us what size and type of metal you need to form. One of the most popular and widely used methods is sheet metal rolling of flat sheet metal pieces or coiled strips that are processed. It comes with rollers.

Sheet Metal Roller 300mm METEX Quality Sheet Metal Pinch Rolls Curved

We offer three types of metal slip rollers for the fabrication industry. Our metal slip rollers are designed to form sheet metal into cylindrical. Slip and plate rolling machines feed sheet metal or metal plates between their long, cylindrical rollers to form flat workpieces into rolls. Make different edge styles on your sheet metal. One of the most popular and.

Sheet Rolling Machine at Hugh Lathrop blog

One of the most popular and widely used methods is sheet metal rolling of flat sheet metal pieces or coiled strips that are processed. It comes with rollers for turning, wiring, burring, beading, and crimping. Make different edge styles on your sheet metal. Our metal slip rollers are designed to form sheet metal into cylindrical. Slip and plate rolling machines.

Sheet Metal Rolling for Commercial Applications

Our metal slip rollers are designed to form sheet metal into cylindrical. Tell us what size and type of metal you need to form. One of the most popular and widely used methods is sheet metal rolling of flat sheet metal pieces or coiled strips that are processed. It comes with rollers for turning, wiring, burring, beading, and crimping. We.

Sheet metal roller plans Artofit

One of the most popular and widely used methods is sheet metal rolling of flat sheet metal pieces or coiled strips that are processed. Tell us what size and type of metal you need to form. Make different edge styles on your sheet metal. Our metal slip rollers are designed to form sheet metal into cylindrical. It comes with rollers.

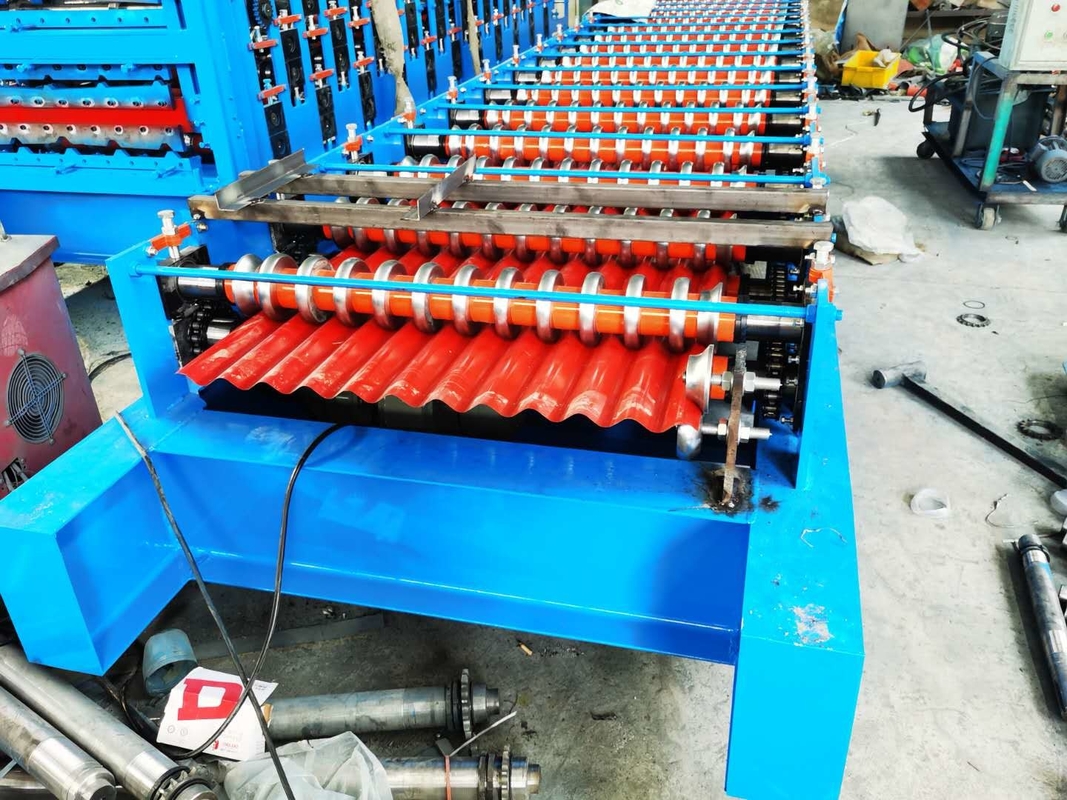

CE 1000mm 3kw Corrugated Sheet Rolling Machine

It comes with rollers for turning, wiring, burring, beading, and crimping. We offer three types of metal slip rollers for the fabrication industry. Make different edge styles on your sheet metal. Slip and plate rolling machines feed sheet metal or metal plates between their long, cylindrical rollers to form flat workpieces into rolls. One of the most popular and widely.

Sheet Metal Rolling Alumac Industries

Make different edge styles on your sheet metal. Slip and plate rolling machines feed sheet metal or metal plates between their long, cylindrical rollers to form flat workpieces into rolls. It comes with rollers for turning, wiring, burring, beading, and crimping. Tell us what size and type of metal you need to form. One of the most popular and widely.

Sheet Metal Roller Conklin Metal Industries

It comes with rollers for turning, wiring, burring, beading, and crimping. Slip and plate rolling machines feed sheet metal or metal plates between their long, cylindrical rollers to form flat workpieces into rolls. We offer three types of metal slip rollers for the fabrication industry. One of the most popular and widely used methods is sheet metal rolling of flat.

Our Metal Slip Rollers Are Designed To Form Sheet Metal Into Cylindrical.

Slip and plate rolling machines feed sheet metal or metal plates between their long, cylindrical rollers to form flat workpieces into rolls. We offer three types of metal slip rollers for the fabrication industry. One of the most popular and widely used methods is sheet metal rolling of flat sheet metal pieces or coiled strips that are processed. Make different edge styles on your sheet metal.

Tell Us What Size And Type Of Metal You Need To Form.

It comes with rollers for turning, wiring, burring, beading, and crimping.