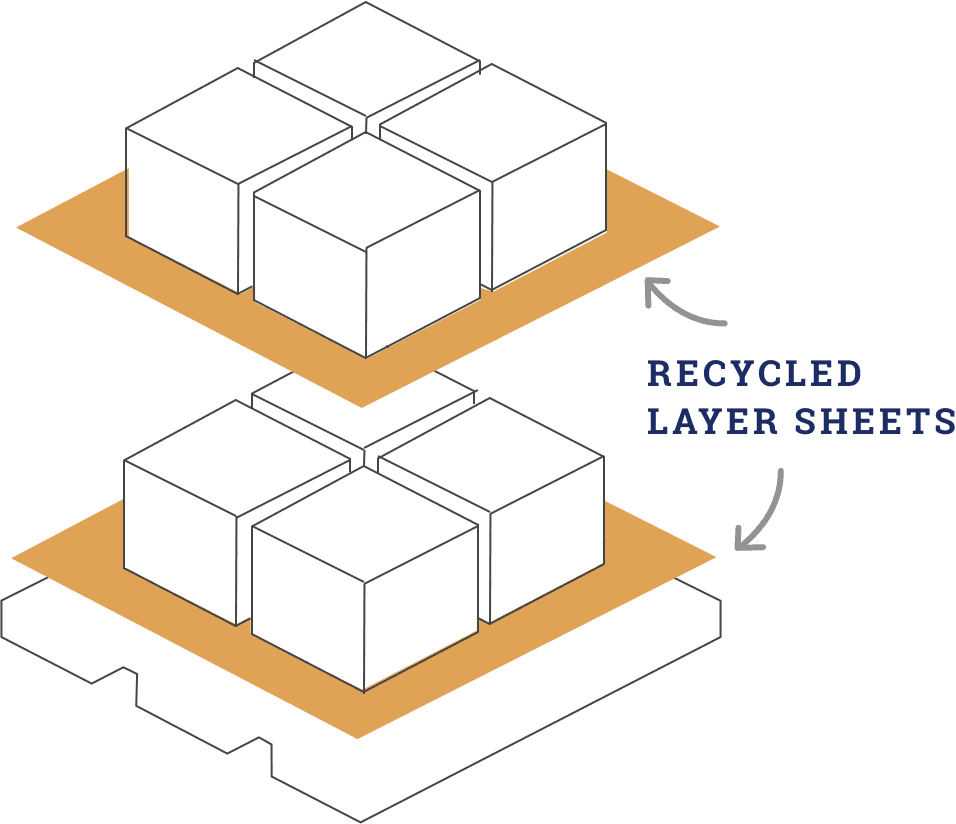

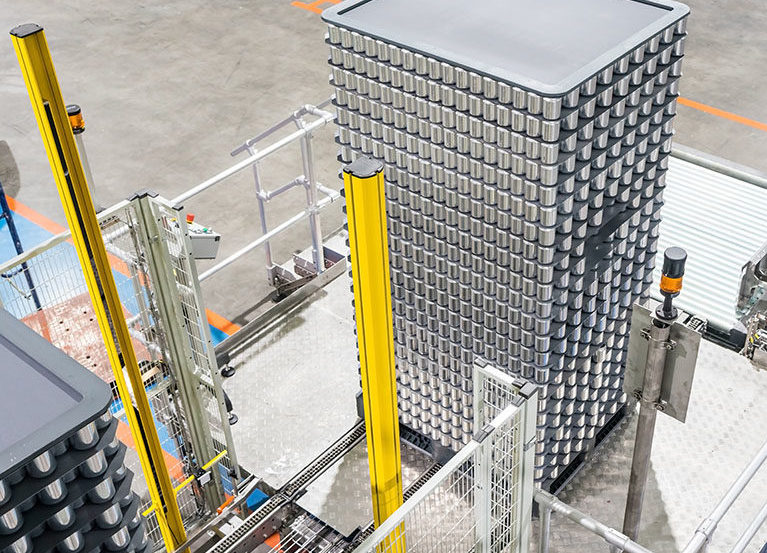

Tier Sheet - What’s the difference between layer, slip, tier, or divider sheets? Tiermaker allows you to create a tier list for anything in seconds. They are typically all the same thing. Different businesses might use the. Quickly use an existing tier list template or upload images to create your. The sheets function as layers between materials or. Layer pads/divider sheets, commonly called tier sheets provide maximum product protection and load stability for unitized loads of food,. Plastic tier sheets, also know as separator sheets and layer pads, offer maximum load stability, reduced contamination and greater product. We sell everything paper and paperboard, from pallet and tier sheets, to interleavers and pads! Tier sheets and divider sheets are separating devices that add stability to a palletized load.

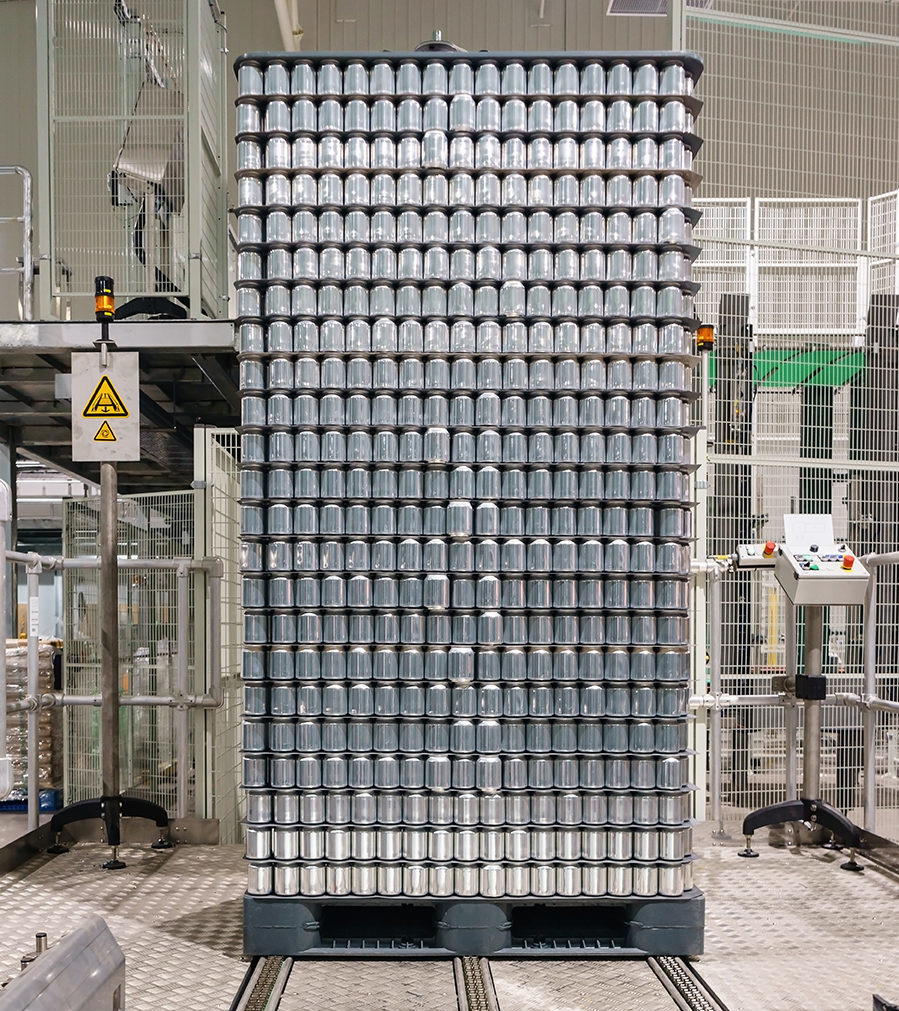

Tiermaker allows you to create a tier list for anything in seconds. We sell everything paper and paperboard, from pallet and tier sheets, to interleavers and pads! Different businesses might use the. Plastic tier sheets, also know as separator sheets and layer pads, offer maximum load stability, reduced contamination and greater product. Quickly use an existing tier list template or upload images to create your. The sheets function as layers between materials or. Tier sheets and divider sheets are separating devices that add stability to a palletized load. What’s the difference between layer, slip, tier, or divider sheets? Tier sheets are designed to separate layers of products, preventing them from sticking together, shifting, or becoming damaged during handling. Layer pads/divider sheets, commonly called tier sheets provide maximum product protection and load stability for unitized loads of food,.

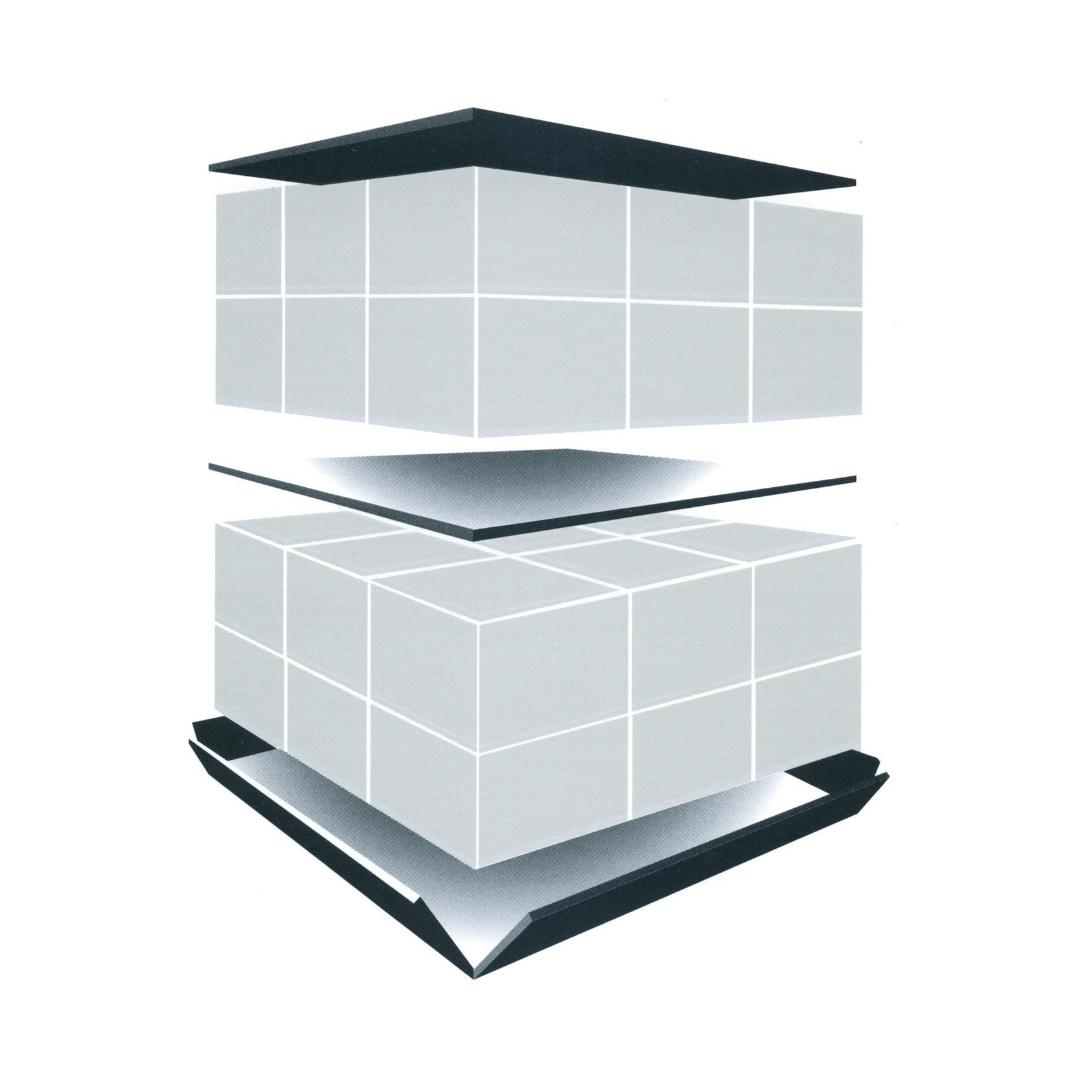

Quickly use an existing tier list template or upload images to create your. Tier sheets are thin paper or paperboard sheets that improve the stability of stacked products and packages. Tier sheets are designed to separate layers of products, preventing them from sticking together, shifting, or becoming damaged during handling. We sell everything paper and paperboard, from pallet and tier sheets, to interleavers and pads! Different businesses might use the. Layer pads/divider sheets, commonly called tier sheets provide maximum product protection and load stability for unitized loads of food,. They are typically all the same thing. What’s the difference between layer, slip, tier, or divider sheets? Tiermaker allows you to create a tier list for anything in seconds. Tier sheets and divider sheets are separating devices that add stability to a palletized load.

Slip Sheets & Tier Sheets Pallet Divider Sheets

We sell everything paper and paperboard, from pallet and tier sheets, to interleavers and pads! Tiermaker allows you to create a tier list for anything in seconds. Tier sheets are designed to separate layers of products, preventing them from sticking together, shifting, or becoming damaged during handling. The sheets function as layers between materials or. Plastic tier sheets, also know.

Tier Sheets Southern States Packaging Company

Different businesses might use the. Tier sheets and divider sheets are separating devices that add stability to a palletized load. We sell everything paper and paperboard, from pallet and tier sheets, to interleavers and pads! The sheets function as layers between materials or. Tiermaker allows you to create a tier list for anything in seconds.

Free Tier List Template for PowerPoint & Google Slides

What’s the difference between layer, slip, tier, or divider sheets? Plastic tier sheets, also know as separator sheets and layer pads, offer maximum load stability, reduced contamination and greater product. Quickly use an existing tier list template or upload images to create your. They are typically all the same thing. Layer pads/divider sheets, commonly called tier sheets provide maximum product.

Plastic Tier Sheets Fresh Pak

Tier sheets and divider sheets are separating devices that add stability to a palletized load. Different businesses might use the. We sell everything paper and paperboard, from pallet and tier sheets, to interleavers and pads! The sheets function as layers between materials or. What’s the difference between layer, slip, tier, or divider sheets?

Slip Sheets & Tier Sheets Pallet Divider Sheets

The sheets function as layers between materials or. Tiermaker allows you to create a tier list for anything in seconds. Tier sheets and divider sheets are separating devices that add stability to a palletized load. Plastic tier sheets, also know as separator sheets and layer pads, offer maximum load stability, reduced contamination and greater product. We sell everything paper and.

4 Common Tier Sheet Questions Answered DuraFibre

Quickly use an existing tier list template or upload images to create your. Different businesses might use the. Tier sheets are thin paper or paperboard sheets that improve the stability of stacked products and packages. Tier sheets are designed to separate layers of products, preventing them from sticking together, shifting, or becoming damaged during handling. They are typically all the.

Plastic Tier Sheets Fresh Pak

Tier sheets are thin paper or paperboard sheets that improve the stability of stacked products and packages. What’s the difference between layer, slip, tier, or divider sheets? Layer pads/divider sheets, commonly called tier sheets provide maximum product protection and load stability for unitized loads of food,. The sheets function as layers between materials or. Quickly use an existing tier list.

Tier Sheets / Plastic Separator Sheets / Layer Sheets Signode

Quickly use an existing tier list template or upload images to create your. The sheets function as layers between materials or. Tier sheets are thin paper or paperboard sheets that improve the stability of stacked products and packages. What’s the difference between layer, slip, tier, or divider sheets? Tiermaker allows you to create a tier list for anything in seconds.

Plastic Tier Sheets Reusable Transport Packaging

Layer pads/divider sheets, commonly called tier sheets provide maximum product protection and load stability for unitized loads of food,. Different businesses might use the. They are typically all the same thing. Quickly use an existing tier list template or upload images to create your. Tier sheets and divider sheets are separating devices that add stability to a palletized load.

Masonite® Hardboard vs DuraSheet Tier Sheets Case Study

We sell everything paper and paperboard, from pallet and tier sheets, to interleavers and pads! The sheets function as layers between materials or. They are typically all the same thing. Tier sheets and divider sheets are separating devices that add stability to a palletized load. Different businesses might use the.

Tier Sheets Are Designed To Separate Layers Of Products, Preventing Them From Sticking Together, Shifting, Or Becoming Damaged During Handling.

Tiermaker allows you to create a tier list for anything in seconds. Quickly use an existing tier list template or upload images to create your. Different businesses might use the. We sell everything paper and paperboard, from pallet and tier sheets, to interleavers and pads!

They Are Typically All The Same Thing.

The sheets function as layers between materials or. Tier sheets and divider sheets are separating devices that add stability to a palletized load. Tier sheets are thin paper or paperboard sheets that improve the stability of stacked products and packages. What’s the difference between layer, slip, tier, or divider sheets?

Layer Pads/Divider Sheets, Commonly Called Tier Sheets Provide Maximum Product Protection And Load Stability For Unitized Loads Of Food,.

Plastic tier sheets, also know as separator sheets and layer pads, offer maximum load stability, reduced contamination and greater product.